Some of our other team members have been experimenting what the best/strongest/easiest method to create the hubs for our geodesic dome sound shell struts.

The equipment we used was -Drop saw to cut angles and a biscuit joiner to cut the slots, but the slots weren't very deep.

We used the band-saw to make deeper slots for thicker hub material to make them more sturdy, but the top of the struts are thin and so it is weaker and the struts might break off.

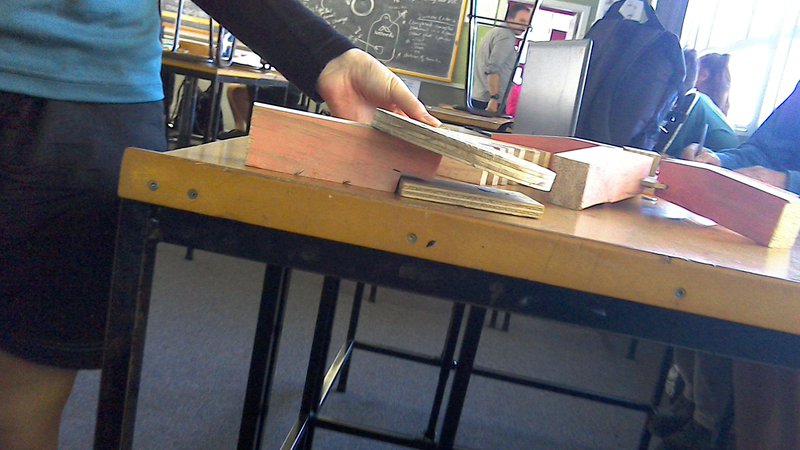

Lastly we cut a notch out of the bottom of the strut to make the top stronger and less likely to break. But we decided because they didn't lock together like the slotted ones it would be harder to assemble. Because the top is cut square with the end we can also add another hub on top of all the versions to give even more strength (as Shontae is holding in the picture below)

We made two different hubs, a circle and a pentagon to see which one works better, after testing it we found that the circle hub would be the best one to use as it is much more easier to assemble because the strut can go anywhere but with the pentagon the strut have to go in a specific place. Although with the pentagon the straight sides fit the bottom of the straight slots better. The thicker hubs out of plywood are a lot stronger than the thin MDF.

If you're considering a career in building and construction, create a BCITO work profile. We'll do our best to get you an apprenticeship when you're finished school.